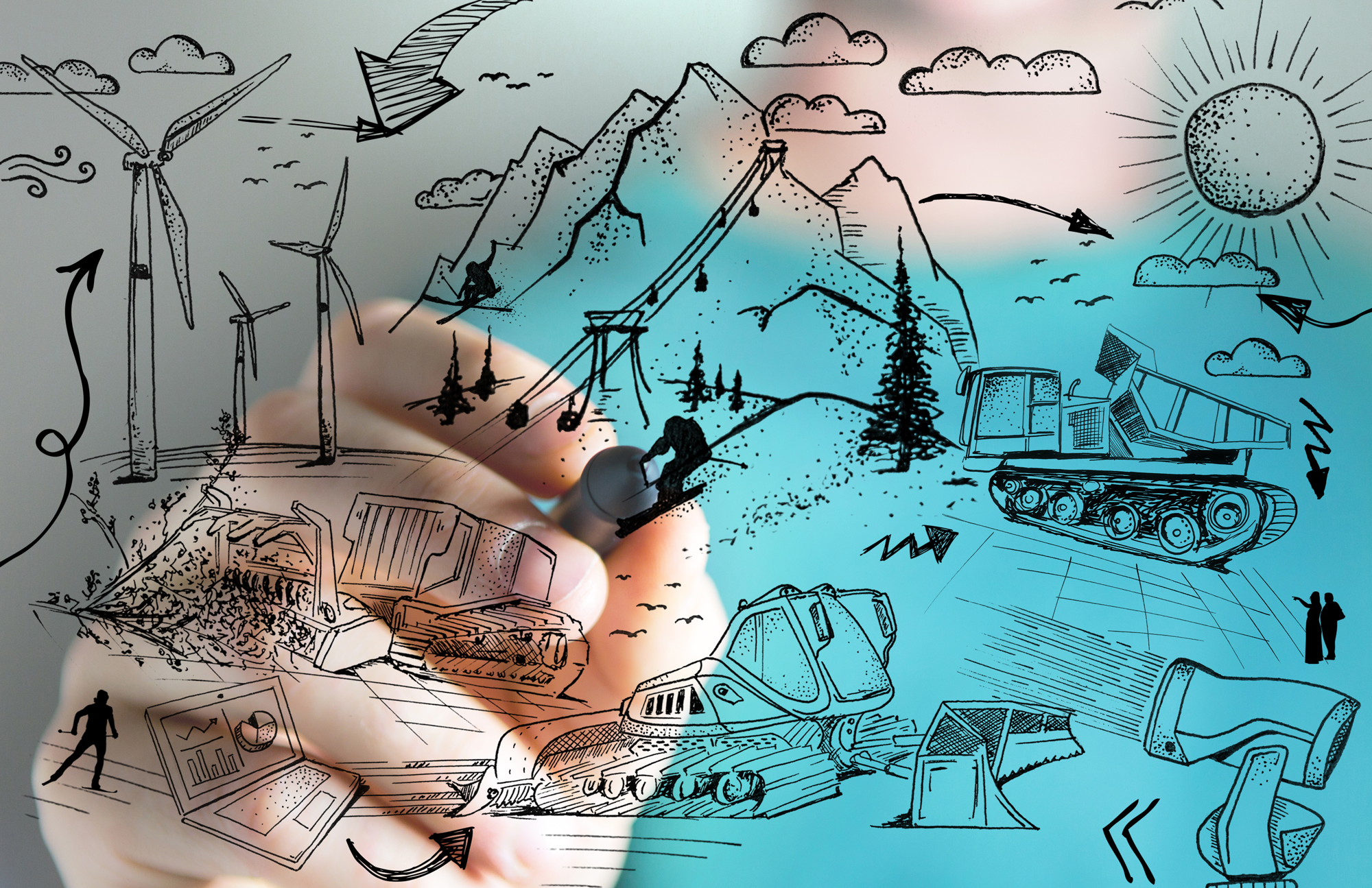

Sustainable Products

Our product designs demonstrate our commitment to sustainability.

Download reportFor a cleaner future

Whether through the selection of clean engines, the attention to efficiency or the focus on minimizing our carbon footprint, we endeavor to set benchmarks in the industries we operate in and help contribute to a cleaner future.

crawler

Carriers

Boosted efficiency and reduced emissions through

Stage V engines and telematics.

Snow

Groomers

Eco-responsible with Stage V engines, alternative fuels, green suppliers

and connected technology to minimize resources.

Vegetation

management

Clean Stage V engines and efficient designs maximize

performance while minimizing carbon emissions.